AP19576638 "Development of an innovative technology for recycling accumulated E-scrap waste to produce pure gold and non-ferrous metals"

Relevance:

There are no technologies for processing E-waste on the territory of Kazakhstan, although their accumulated volumes in recent years are very significant. The relevance and significance of the project are enhanced by the fact that there is no rational technology for processing E-waste. Many valuable, technologically recoverable metals are irretrievably lost with them. E-waste is a complex conglomerate of precious metal alloys, the properties of which depend on the type of their use, the design of electrical goods (electronic circuit boards, smartphones) and many other factors. This determines the need for comprehensive studies of the composition and properties of E-waste in order to use them as an additional source for the extraction of gold and valuable metals in the form of commercial products.

Purpose:

Creation of an innovative environmentally friendly, highly efficient waste-free technology for the disposal of accumulated E–scrap waste with the selective extraction of competitive commodity products – pure gold and non-ferrous metals by reducing-chlorinating firing of pre-prepared powdered E-scrap waste.

Expected and achieved results:

Expected results: Development of an environmentally friendly combined waste-free technology for complex processing of E-waste to produce commercial products with high added value.

The following results have been achieved:

The analysis of known technologies for the processing of E-waste has been carried out.

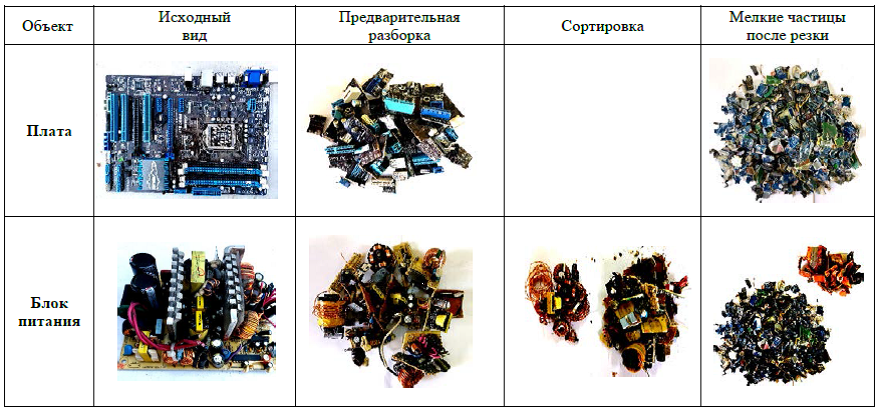

Based on comprehensive studies, including physico-chemical and mineralogical studies of various types and composition of E-waste, new data on the forms of metals in electronic scrap waste have been obtained.

New data on the thermodynamics of the interaction of gold and related metals with various chlorine-containing reagents have been obtained.

The technological parameters of chlorinating firing have been established, ensuring high up to 93% recovery of gold from E-waste.

Research team members with their identifiers (Scopus Author ID, Researcher ID, ORCID, if available) and links to relevant profiles:

Zholdasbay Е.Е. – ORCID ID: 0000-0002-9925-4435, Scopus Id: 56709664900, Web of Science ResearcherID:

AAD-7185-2021

Argyn A.A. – ORCID – 0000-0001-5001-4687, ResearcherID – AAW-8164-2020, ScopusAuthorID – 57217683061.

Kurmanseitov M.B. – ORCID ID: 0000-0001-5008-2866, Scopus Id: 57195364745, Web of Science ResearcherID:

AAD-9310-2021

Daruesh G.S. – Researcher ID – AGB-3218-2022, Scopus Author ID – 57212931013, ORCID – 0000-0001-6739-1569

Dosmukhamedova K.S. – no

List of publications with links to them:

According to the results, published articles:

- Zholdasbay E.E., Argyn A.A., Kurmanseitov M.B., Tazhiev E.B., Ichev V.A. On the issue of choosing a technology for processing E-waste // International Journal of Applied and Fundamental Research. 2023. No.7. P.28-33.

- Zholdasbai E.E., Argyn A.A., Kurmanseitov M.B., Daruesh G.S., Ichev V.A. Comparative qualitative assessment of E-waste // Scientific Review. Technical sciences. 2023. No. 4. P.11-16.

- Zholdasbay E.E., Argyn A.A., Kurmanseitov M.B., Dosmukhamedov N.K. Analysis of the current state and prospects of electronic waste processing // Mining Journal of Kazakhstan. 2023. No.12. P.12-17.

- Zholdasbay E.E., Argyn A.A., Kurmanseitov M.B., Dosmukhamedova K.S., Daruesh G.M. Study of the influence of temperature and duration of chlorinating roasting on the extraction of gold from E-waste // Kompleksnoe Ispolzovanie Mineralnogo Syra = Complex Use of Mineral Resources. 2025. 333(2). Р. 51-58. DOI: https://doi.org/10.31643/2025/6445.17

- Zholdasbay Ye.E., Dosmukhamedov N.K., Argyn A.A., Kurmanseitov M.B., Tzhiev Ye.B., Daruesh G.S., Koishina G.M. Technological and environmental aspects of electronic waste recycling // Metallurgist. 2024. No.2. P.105-110. DOI: https://doi.org/10.1007/s11015-024-01727-0 (WOS, Scopus, Q3, Percentil -46)

- Zholdasbay E.E., Argyn A.A., Dosmukhamedov N.K., Kaplan V.A. Gold recovery from electronic scrap waste by low-temperature chloridizing roasting // Non-ferrous Metals. 2024. Vol.1. P.22-27. DOI: 10.17580/nfm.2024.01.04 (Scopus, Q2, Percentil-46)

Patents:

–

Figure 2. General view of the RPP-12 (T) device